Our Commitment to Excellence

Certified Processes & Compliance

ISO 9001:2015 & AS9120B Certified

Ensuring strong quality management and aerospace-level supply chain practices.

AS6081 & AS6171 Testing Standards

Mitigating risks of counterfeit and fraudulent electronic parts through 3rd-party testing labs.

ECCN & HTS Guidance

Expert classification for international trade and export control.

Supplier Qualification

Onboarding Questionnaire & Documentation

Suppliers must complete a detailed qualification survey covering traceability, certifications, and quality controls.

Certification Verification

We validate ISO 9001, AS9120, AS6081/AS6171 compliance, ITAR registration, and other industry standards as applicable.

Financial & Trade References

Stability is confirmed through credit checks, references, and performance history.

Blacklist/Watchlist Screening

All suppliers are screened against ERAI, GIDEP, denied-party, and sanction lists.

Rigorous Testing & Authentication

Every incoming part from the open market is thoroughly inspected in our QA department. With our in-house inspection and third-party testing, we can provide advanced inspection and verification services, including:

Visual Inspection

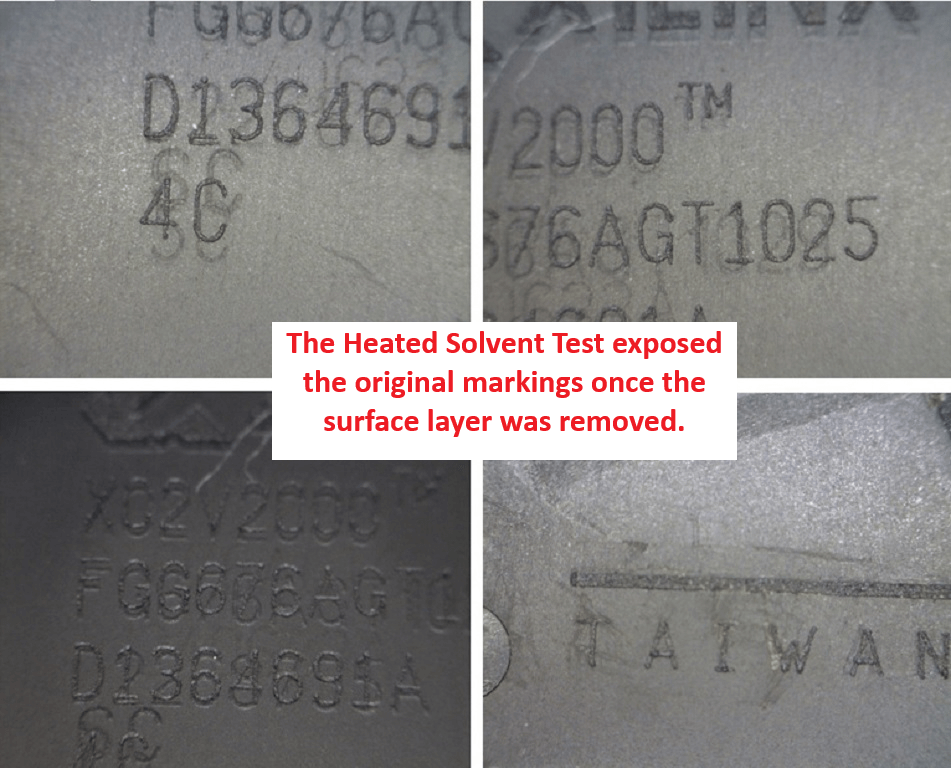

Marking Permanency & Resurfacing Test

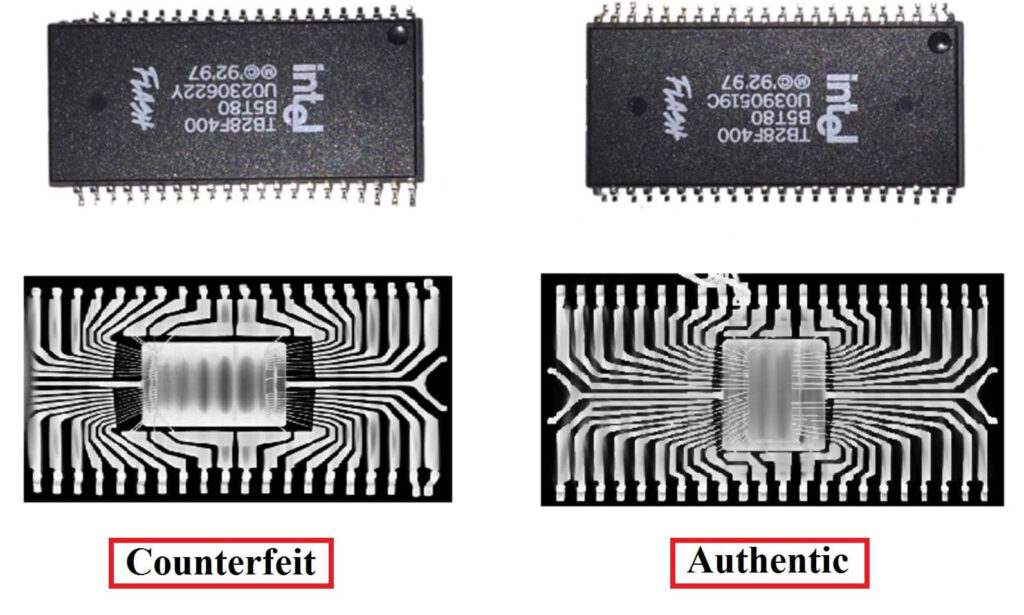

X-Ray

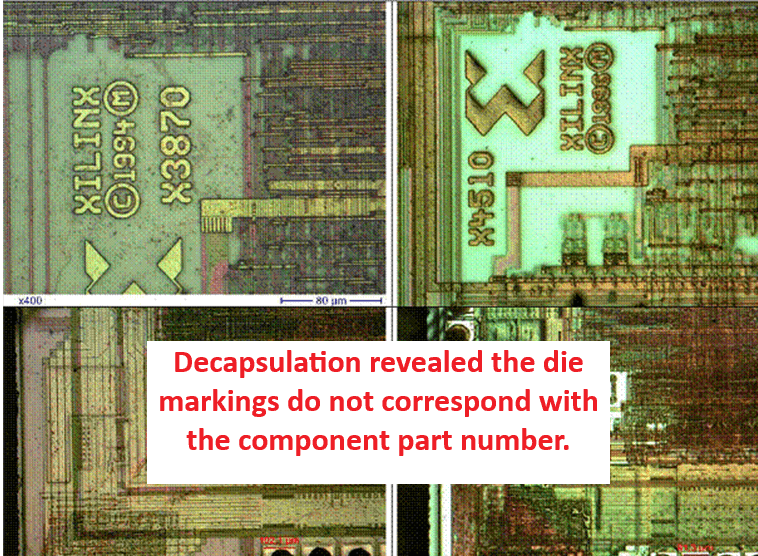

Decapsulation & Die Verification

Electrical Testing

Jtag Boundary Scan

C-SAM

Using pulse-echo imaging, C-SAM acoustic microscopy detects voids, cracks, and delamination, and can see through blacktopping to uncover markings.

Full Documentation

Traceability & Transparency

We know that reliability in the supply chain is non-negotiable. That’s why we maintain:

Golden Sample Comparisons

Benchmarking authenticity at every stage.

Date Code & Label Alignment

Ensuring packaging, paperwork, and parts match precisely.

Supplier Vetting

Partnering only with vetted OEMs, CEMs, and trusted global distributors.

Audit Readiness

Robust internal systems to prepare for and exceed customer and industry audits.

Protecting Your Supply Chain

Authentic

Verified through multi-step inspections and trusted labs.

Reliable

Backed by test data and quality certifications.

Traceable

Supported with complete documentation and supply chain visibility.

Quality You Can Trust

When you choose NewGen Technology, you’re choosing a partner committed to protecting your business. From concept to end-of-life, our dedication to quality ensures you receive only the highest-performing, fully validated components—because your success depends on nothing less.